The redevelopment of the factory began less than three years after its purchase, when a new counting house and warehouses were added onto the original silk mill. However, George Palmer faced a major hurdle in his plans for expansion of the site.

An island site

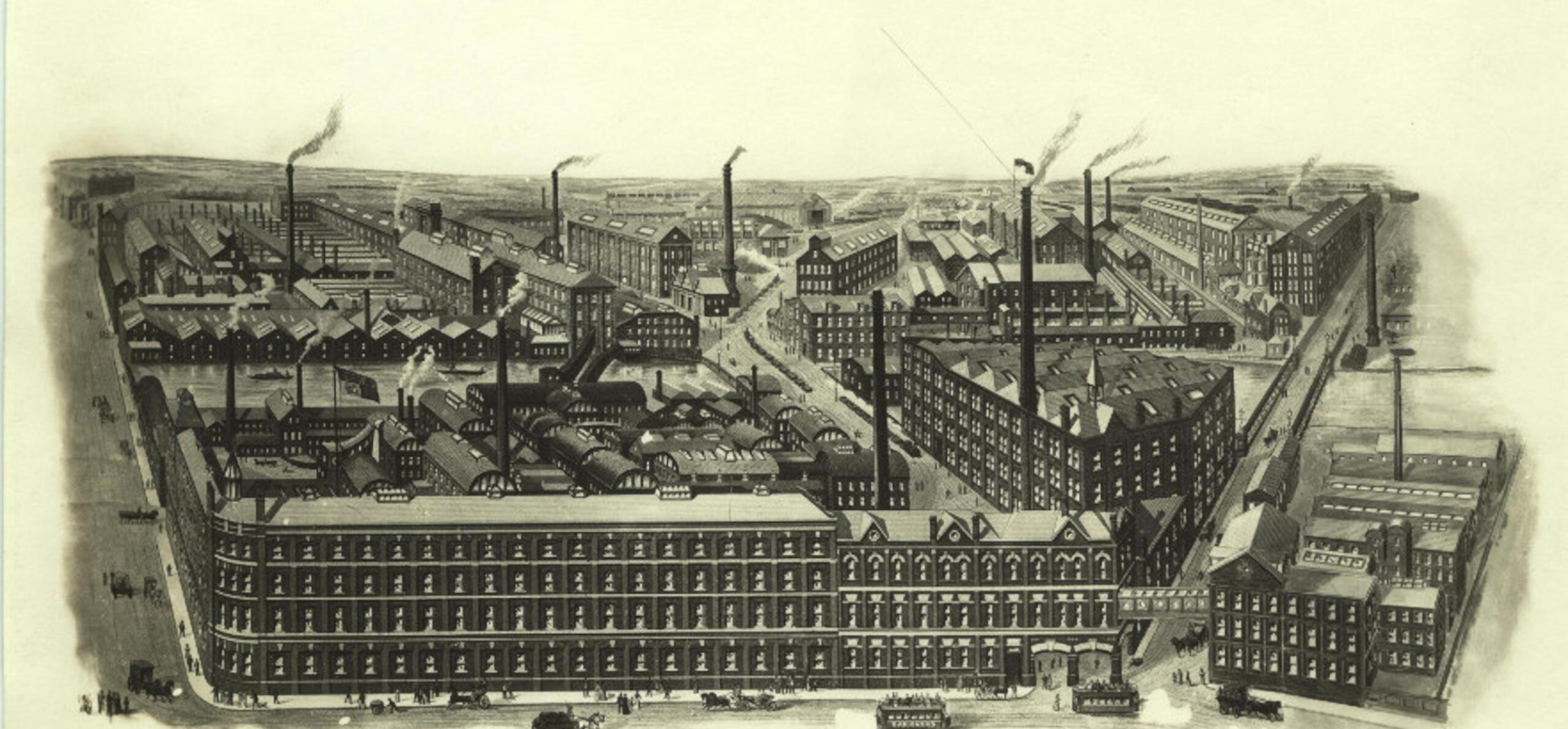

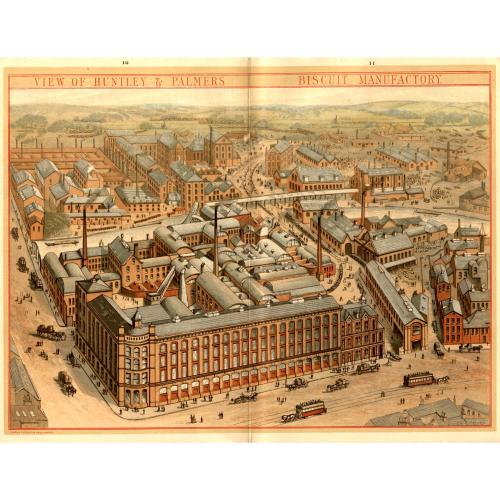

The factory was positioned on an island site between the River Kennet and the Kennet and Avon canal. To the south and west of the factory was the town of Reading and to the east was the meeting point of the canal and river. The only possible direction for expansion, without having to move the site altogether, was north.

This birds-eye view from about 1889 shows how cramped the site had become as the factory grew in a piecemeal fashion. However, the factory's convenient location is clear as the canal can be seen running through the centre of the site.(REDMG : 1997.82.135)

In 1868 George Palmer acquired the land north of the factory on the other side of the river. Four years later Huntley & Palmers purchased the Cannon brewery factory and the last piece of the jigsaw fell into place. In November 1873 the new buildings were declared open for business.

Bridges and tramlines

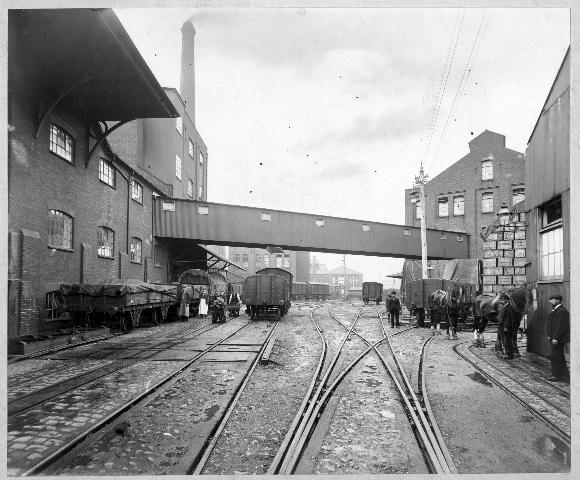

As the new factory spread across the river, many bridges were constructed to enable goods to move around the factory. Goods were transported using small tram-trucks and by 1900 there were about 12 miles of narrow gauge tramlines within the works.

Locomotives transported some material around the site, but the majority of internal transport was on wagons pulled by horses or pushed by hand on narrow gauge tramlines. Above the tracks, a bridge connects manufacturing departments. (REDMG : 2002.72.35)

The Bagnall Fireless Locomotives

Huntley & Palmers locomotives also had to work within the warehouses. Conventional locomotives were unsuitable because of fumes and danger of fire from sparks so the firm purchased special locomotives which were filled with high pressure steam from a stationary boiler. Each filling took 15 minutes and gave 2 hours running time.

In 1932 the company purchased a pair of William Bagnall fireless steam locomotives for shunting vans at the factory. (REDMG : 1997.130.196)

Departments of the factory

By 1898 there were five manufacturing units and many products, such as sugar wafers, had their own factory.

This was the chocolate department, with their 'chocolate coating machines'. It was, apparently, a prestigious department to work in - the aura of the luxury biscuits it produced was thought to rub off on the women working there. (REDMG : 1997.130.112)

The Laboratory

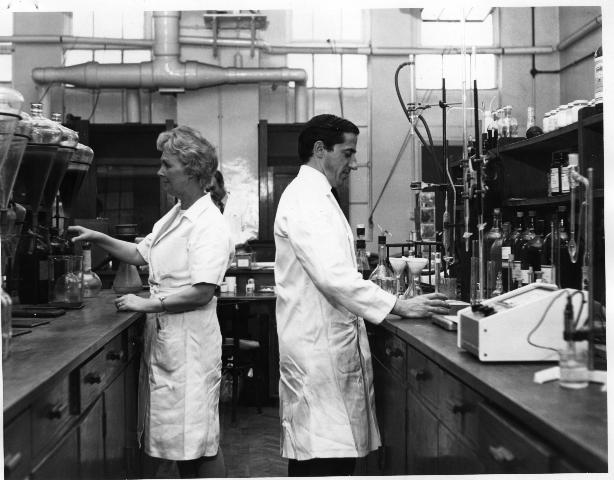

In addition to the manufacturing departments, Huntley & Palmers also had laboratories to test the ingredients coming in from all over the world. Material samples were sent to the laboratory for chemical analysis to show the required purity and to examine their behaviour in manufacturing processes.

By the 1960s the laboratory also had to carry out a special examination on all products destined for the USA. This was necessary because of the exacting food laws in North America. (REDMG : 1997.130.303)

The office

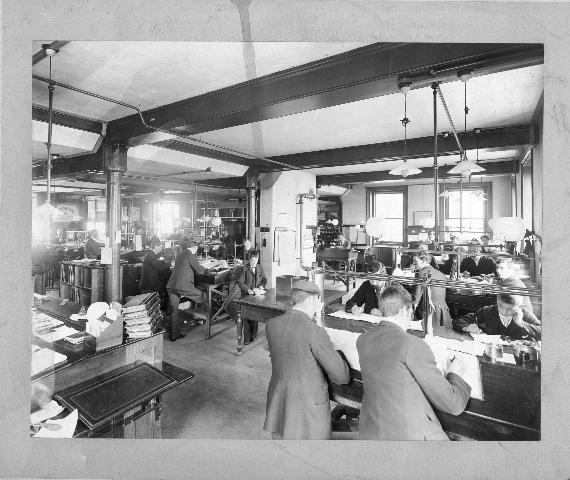

As with any large firm, in addition to those employed in the manufacturing, there was a large staff of clerks who conducted the extensive London, continental and foreign business of the firm.

After the 1880s, the number of office staff increased more rapidly than the number of factory employees as the first signs of inefficiency began to show. As late as 1930 statistics were still produced by hand rather than by machine. (REDMG : 1997.130.573)

The Huntley & Palmers site was highly sophisticated and state of the art. In the next section, learn about the many people and notable figures from public life who visited the factory.